The Espresso Machine Restoration site

A non-commercial site for those interested in espresso equipment repair and restoration.

The pump and motor are used to provide the required water pressure to be able to make espresso. If we take a

quick look back through time the early espresso machines used the pressure of boiling water to force it's way

through the coffee grounds. This was then succeeded by the lever arrangement in which a powerful spring was

compressed by the operator. As the spring was compressed the hot water would fill a chamber with the water to be

used for brewing. As the lever was released the spring pressure as it returned to it's original state would force the

water through the grounds at a pressure suitable for espresso. The lever was subsequently replaced by a pump

and an electronic motor to provide the correct pressure.

The pump and motor also serve the purpose of filling the boilers with water upon installation.

Rotary pumps are used in all commercial espresso machines both semi and fully-auto. Many prosumer machines

may be ordered with a rotary pump rather than the stock Ulka vibe pump.

By their very nature rotary pumps are usually plumbed into the mains water supply.

There are far better sites that can explain it better than I could. One great site is here. Remember we are dealing

with rotary vane pumps.

What do they consist of?

Pump (Procon), Motor, Clamp ring, mounting base, check valve and start capacitor.

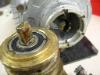

The pictures above display a dirty pump, which is our subject for an overhaul later on.

The motor

The motor is usually made by a company RPM spa. The specifications should be 300w, 220V, 50HZ - but that may

vary depending upon you country. The motor may come in various forms. For example the one in the picture has

heatsink fins on the side. Some dont. Some also have a smooth outer jacket. At the rear of the fan is a small fan

enclosed in a black plastic case to keep the motor cool. The motor is thermally protected in case of overheating it

will cut out.

Start capacitor

The motor requires a capacitor to give it the initial push so that it is immediately up to speed. Imagine switching on a

ceiling fan or a desktop fan and see how it takes time to get up to operating speed. Obviously this is not acceptable

in our espresso machines (although a gentle ramp up to pressure is another issue!) so we use a start capacitor.

The capacitor is similar to a battery but in this case the capacitor stores electrons for when it is required. Capacitor

are measured in Farads. A 1 farad capacitor would be huge generally our capacitors are in microfarads (millionths

of a farad). The microfarad rating of your capacitor is printed on the side of the capacitor and may be 6uf, 10uf or

20uf.

The pumps in espresso machines are usually made by Procon. The pump has two female plumbing connections -

an inlet and an outlet. The inlet is marked by an arrow, moulded into the brass, pointing downwards.

The pump has a manual adjustment so that you can fine tune the output pressure to achieve your 8-9 bars.

It should be noted that the pump will not be able to maintain a stable output pressure e.g. 8.5 bars if the input

pressure from your mains water supply fluctuates. For example if you share a water line with a laundry machine or

dishwasher then you will need to install a water regulator BEFORE the pump. That will absorb any fluctuations in

mains water pressure that will mean a stable output pressure from the pump.

The pump is mounted onto a metal base. You can mount this to a wall or shelf as it has holes drilled into it. It is

prone to rust!

The clamp ring secures the pump and motor together.

Check-valve

Typically there is a check-valve fitted into the outlet female fitting on the pump. This allows water to flow from the

pump but cannot return.

Motor trouble

In general the motor is a reliable piece of equipment. The only trouble I have known is foreign objects and liquids

getting into the motor. A typical installation of an external pump is under the machine next to the sink and the

grease trap. It is inevitable that all kinds of dirt, dust, grease and insects will be in that cupboard. It also certain that

at some time water or coffee dregs will fall onto the motor. Therefore it is a good idea to check that the motor is

clean and grease free. If you have a pump that wont work also check for screws or anything that would stop the

motor turning.

Capacitor trouble

More common that a dead motor will be a problem with the capacitor. The capacitor will weaken over time and will

require replacement. Symptoms of this would be if the motor refuses to turn at all and if there is a delay in starting

after the brew switch has been activated. If you have a "dead motor" then the first thing I would do is check that the

voltage is going to the motor with a multimeter. If it is and you can turn the motor by hand (remove pump and turn

spindle) then it is the start capacitor. Replace with an exact same uf rated capacitor.

Pump problems

There are numerous causes that will cause you problems. In summary these are dirty water, limescale, foreign

objects and air. The following is a fairly typical pump problem.

Problem Pump not turning but motor "hums" i.e. it is trying to turn and this is confirmed by an electrical burning

smell.

Cause Dirt and limescale have caused the vanes to seize up after a period of inactivity (machine in storage). Even

turning the pump shaft by hand is impossible.

Remedy Remove pump clamp, all hoses and valves from the pump. Attempt to turn the pump shaft with a spanner.

If it does not move under slight force then stop. We will try again after cleaning. Prepare a container of hot water

and citric acid. e.g. a 32oz pitcher and 1 tablespoon of citric acid.

I would only leave the pump inside for a maximum of 30 mins. Every 5 mins or so I would turn the shaft to get things

moving around inside. If your shaft was impossible to move before, after 5 mins soaking now attempt to force it to

move. After 30 mins give it a through rinse with fresh water and then connect to your motor and turn it over for

about 5 mins by pumping clean water.

Many a pump has been saved this way!

Problem - A noisy pump.

Cause - Air in the water line. Cavitation.

Remedy - Ensure your water supply is ok. Run water through until noise ceases. If the noise remains your vanes

may have been damaged. If the pressure is OK and you can accept the noise you can keep the pump. If not you

need a new one.

DO NOT TAKE APART PROCON PUMPS - THEY CANNOT BE REBUILT!

will say yes, but please ask first!

Email me here.